Introduction: Chillers — The Silent Cooling Giants of Modern Infrastructure

Ever wonder how skyscrapers, data centers, or massive malls remain ice-cold even during peak summer heat waves? The secret lies in one of the most powerful and often overlooked components of HVAC systems—chillers.

A chiller is a mechanical refrigeration system designed to remove heat from a liquid, typically water, which is then circulated through heat exchangers to cool air or machinery. In simple terms, it’s the cooling engine behind most large-scale air conditioning systems.

Whether it’s maintaining climate control in a hospital or ensuring servers don’t overheat in data centers, chillers are essential for high-efficiency, reliable cooling. Their flexibility, performance, and scalability make them indispensable across various industries.

What Is a Chiller?

A chiller is a refrigeration system that removes heat from a process fluid (usually water or a water-glycol mixture) and transfers that heat to the environment. The cooled fluid is then circulated through a building or system to provide cooling.

The basic operation of a chiller involves heat exchange via the vapor compression cycle or absorption cycle. The chilled water is typically distributed through air handlers or fan coil units to regulate indoor temperatures.

Chillers are widely used in HVAC systems for hospitals, airports, commercial buildings, data centers, manufacturing plants, and even power stations.

How Does a Chiller Work?

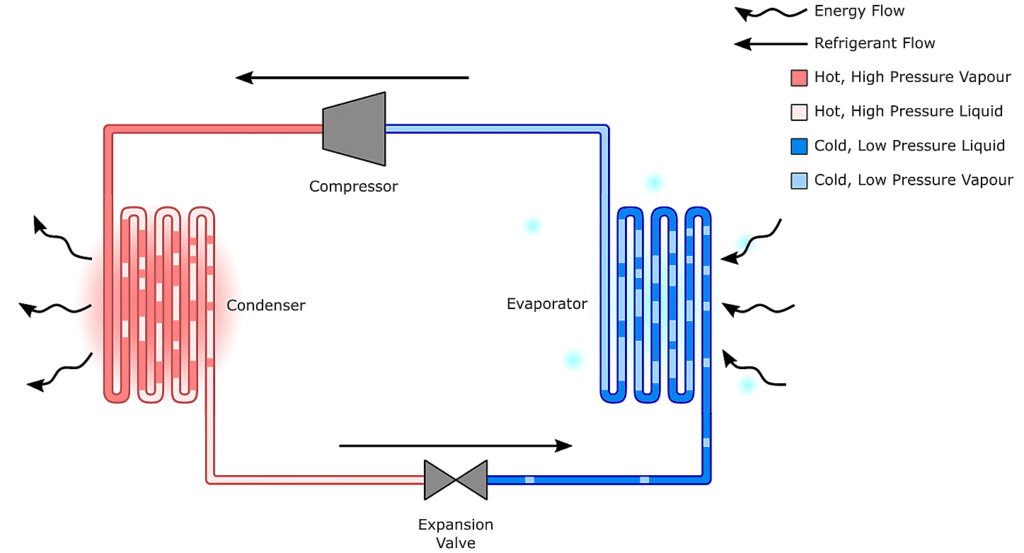

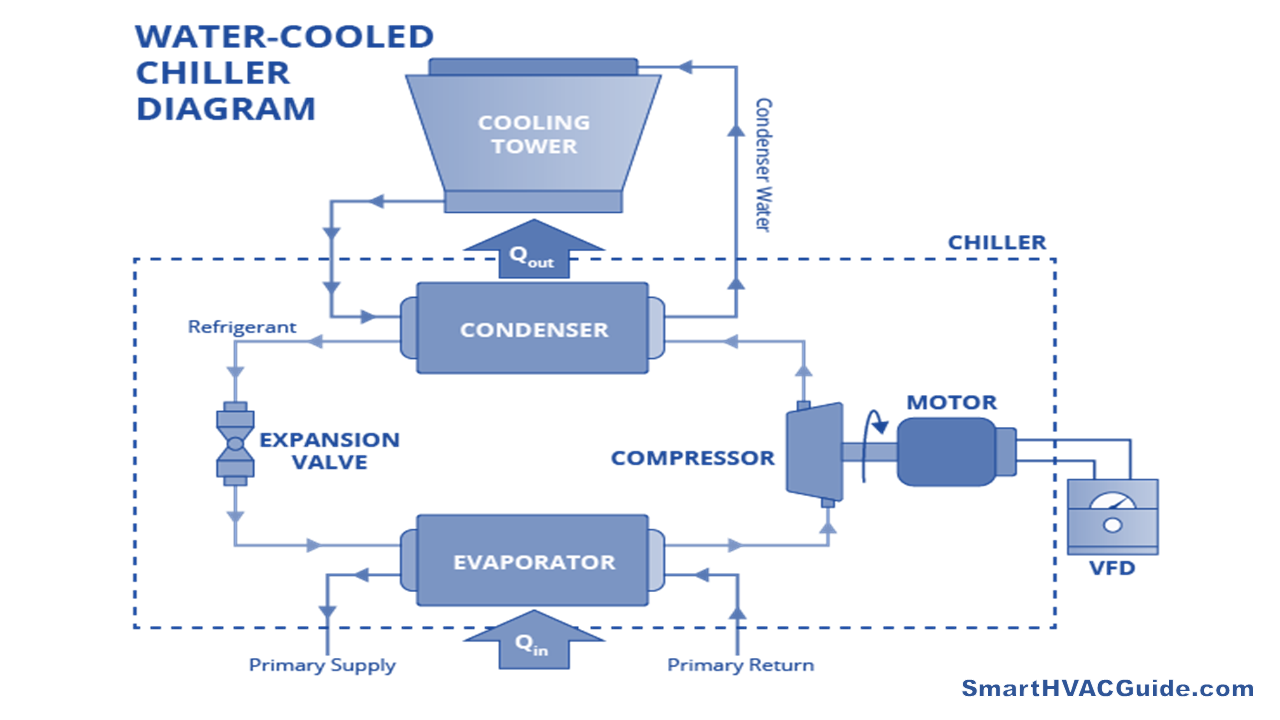

Understanding how a chiller system operates is key to grasping the backbone of modern HVAC systems. Whether used in high-rise buildings, industrial plants, or hospitals, a chiller’s function relies on the refrigeration cycle—a continuous loop that efficiently transfers heat from one area to another. This cycle comprises four major stages: Evaporation, Compression, Condensation, and Expansion. Let’s dive into each step to see exactly how a HVAC chiller keeps spaces and processes cool.

1. Evaporation – Heat Absorption Begins

At the heart of the cooling process is the evaporator, where chilled water and refrigerant interact. In this stage, low-pressure liquid refrigerant flows through evaporator coils, while warm water from the building or process equipment circulates over these coils. The refrigerant absorbs heat from the water, causing it to boil and vaporize into a low-pressure gas. This results in a significant drop in water temperature, which is then recirculated through air handlers or industrial equipment. This process is central to the chiller’s cooling capacity, as it removes unwanted thermal energy from the system.

2. Compression – Pressurizing the Refrigerant

The now gaseous refrigerant exits the evaporator and enters the compressor—arguably the most critical component of a chiller system. The compressor’s job is to raise the pressure and temperature of the refrigerant vapor. It does this by compressing the gas into a high-pressure, high-temperature state. This step is essential for moving the refrigerant through the rest of the system and enabling effective heat rejection in the next stage. Different types of compressors—scroll, screw, reciprocating, or centrifugal—are used depending on the chiller type and capacity needs.

3. Condensation – Heat Rejection to Air or Water

Once compressed, the superheated refrigerant gas moves into the condenser, where it must release the heat it previously absorbed. In air-cooled chillers, this heat is expelled into the atmosphere via fans and condenser coils. In water-cooled chillers, the heat is rejected into a separate water stream that is cooled in a cooling tower. As the refrigerant gives off heat, it transitions back into a high-pressure liquid, completing the heat rejection process. Efficient heat transfer at this stage is critical to maintaining chiller performance and efficiency.

4. Expansion – Resetting the Cycle

In the final stage, the high-pressure liquid refrigerant flows through an expansion valve—also known as a thermal expansion valve (TXV) or electronic expansion valve (EXV). Here, the pressure of the refrigerant is drastically reduced, which causes a corresponding drop in temperature. This low-pressure, cold liquid refrigerant is now ready to enter the evaporator once again and repeat the cycle. This controlled expansion is vital to regulate how much refrigerant enters the evaporator based on load conditions.

🔁 The Continuous Cooling Cycle

This four-step refrigeration cycle runs continuously while the chiller is in operation, enabling the system to provide consistent and scalable cooling. Whether it’s a centrifugal chiller serving a 40-story building or an industrial screw chiller cooling a manufacturing process, this cycle ensures effective heat extraction and rejection in every use case.

For a visual understanding of the refrigeration cycle and detailed technical schematics, refer to this excellent resource by ASHRAE:

🔗 ASHRAE Refrigeration Fundamentals (PDF)

Types of Chillers

A. Based on Compressor Technology

1. Reciprocating (Piston) Chillers

- How it works: Uses pistons to compress the refrigerant.

- Best for: Small to mid-sized installations (5–200 tons).

- Pros: Inexpensive, easy to maintain.

- Cons: Noisy, less durable than other types.

- Keyword Focus: Reciprocating chiller compressor

2. Scroll Chillers

- How it works: Two scrolls spiral together, compressing refrigerant smoothly.

- Best for: Medium capacities (10–300 tons).

- Pros: Quieter and more efficient than reciprocating.

- Cons: Limited in high-capacity applications.

- Keyword Focus: Scroll compressor chiller

3. Screw Chillers (Helical Rotary)

- How it works: Twin helical rotors compress the refrigerant.

- Best for: Large-scale commercial & industrial HVAC (100–2,000 tons).

- Pros: Energy-efficient, capable of variable load operation.

- Cons: Expensive, requires skilled maintenance.

- Keyword Focus: Industrial screw chiller

4. Centrifugal Chillers

- How it works: High-speed impellers compress refrigerant via centrifugal force.

- Best for: Massive cooling needs (200–10,000+ tons).

- Pros: Best energy efficiency, low maintenance.

- Cons: Surge risk at low loads, high initial cost.

- Keyword Focus: Centrifugal chiller HVAC

B. Based on Cooling Method (Heat Rejection)

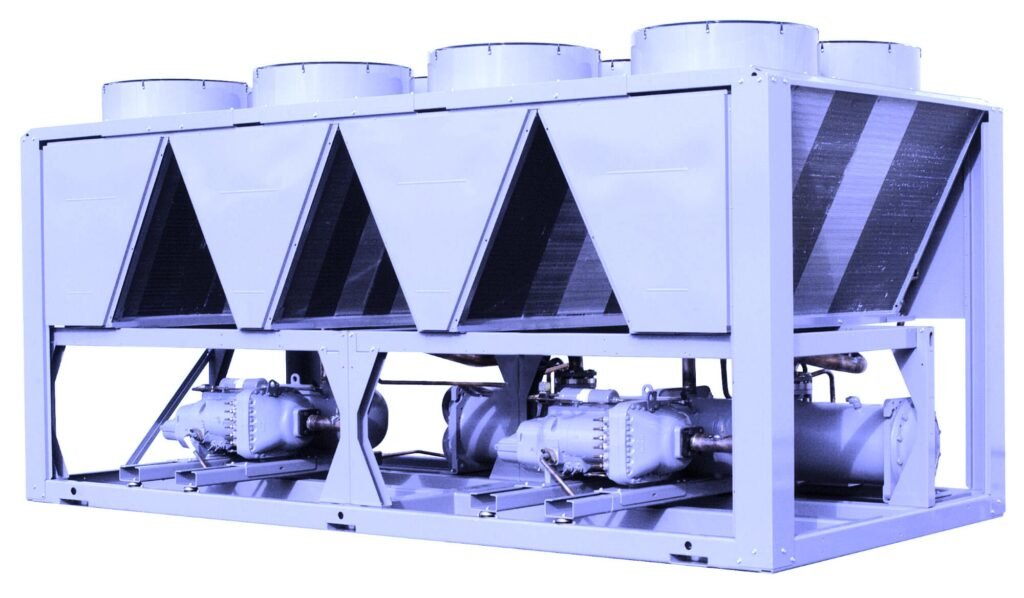

1. Air-Cooled Chillers

- How it works: Uses air fans to cool refrigerant via outdoor ambient air.

- Best for: Small to mid-sized buildings, water-scarce locations.

- Pros: Easy installation, no cooling tower.

- Cons: Lower energy efficiency.

- Keyword Focus: Air-cooled vs. water-cooled chille

2. Water-Cooled Chillers

- How it works: Heat is rejected via water through a cooling tower.

- Best for: Large commercial complexes.

- Pros: Up to 50% more efficient than air-cooled systems.

- Cons: Requires water treatment and more maintenance.

- Keyword Focus: Water-cooled chiller system

3. Evaporatively Cooled Chillers

- How it works: Hybrid model using both air and water (spray mist + fan cooling).

- Best for: Dry climates needing higher efficiency with water constraints.

- Pros: Energy-efficient and water-optimized.

- Cons: More complex to maintain.

C. Based on Condenser Type

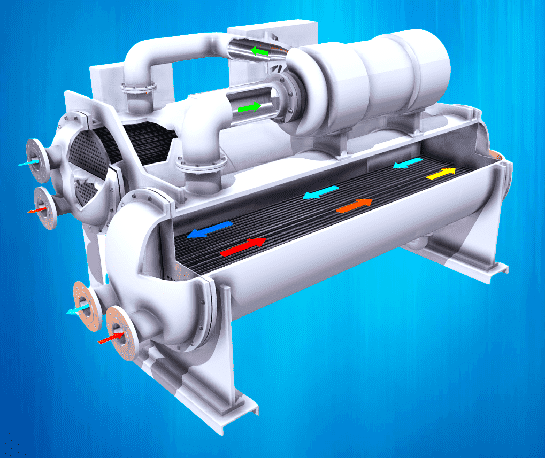

1. Shell-and-Tube Condensers

- Design: Refrigerant moves through tubes while water flows over them.

- Pros: Durable and suitable for high-pressure applications.

- Cons: Bulky and harder to clean.

2. Plate Heat Exchangers

- Design: Heat is transferred through stacked metal plates.

- Pros: More efficient and compact than shell-and-tube.

- Cons: Clogs easily, not as robust.

D. Based on Refrigerant & Energy Source

1. Vapor Compression Chillers

- Energy Source: Electric power.

- Refrigerants: R-134a, R-410A, R-32 (eco-friendly options).

- Usage: Most commercial and industrial applications.

2. Absorption Chillers

- How it works: Uses heat instead of electricity to drive the cycle.

- Refrigerant: Water + Lithium Bromide.

- Best for: Using waste heat or solar energy.

- Keyword Focus: Absorption chiller vs. electric chiller

E. Based on Application

1. Industrial Chillers

- Uses: Cooling in plastic, food, laser, chemical industries.

- Features: Heavy-duty, customizable.

2. Commercial Chillers

- Uses: Office buildings, hotels, hospitals.

- Features: Quiet operation, modular designs.

3. Portable Chillers

- Uses: Temporary installations, events, server rooms.

F. Emerging & Niche Types

- Magnetic Bearing Chillers: Oil-free, 50% lower energy use.

- Thermoacoustic Chillers: No moving parts (experimental stage).

- Solar-Powered Absorption Chillers: Uses renewable energy for operation.

Why Are Chillers Essential for HVAC Systems?

Chillers are the heart of large-scale HVAC systems, providing efficient, centralized cooling for skyscrapers, hospitals, data centers, and industrial facilities. Unlike standard air conditioners, which cool air directly, chillers cool water or glycol, which is then circulated through air handlers or process equipment. This method is far more energy-efficient for big spaces, as water absorbs heat 40x better than air, reducing energy consumption and operational costs.

Additionally, chillers offer precise temperature control, critical for environments like laboratories, server rooms, and manufacturing plants. They can handle heavy cooling loads 24/7, support thermal energy storage, and integrate with smart HVAC automation. Without chillers, large buildings would rely on inefficient, decentralized cooling systems, leading to higher costs, inconsistent temperatures, and frequent breakdowns. Simply put, chillers are the unsung giants that make modern climate control possible.

- Energy Efficiency: More effective than standard direct expansion (DX) air conditioners.

- Temperature Precision: Critical for sensitive environments like labs or data centers.

- Scalability: Capable of cooling multi-story buildings and large industrial zones.

- Durability: With proper chiller maintenance, units can last 15–30 years.

Common Chiller Problems & Maintenance Tips

Common Problems:

- Refrigerant Leaks: Refrigerant is the lifeblood of any chiller system, and even a minor leak can severely impact performance. When refrigerant levels drop, the chiller has to work harder to achieve the desired cooling output, which leads to increased energy consumption and reduced efficiency. Over time, this strain can cause premature wear on the compressor and other components. Detecting and repairing leaks early is crucial for maintaining system integrity and avoiding costly breakdowns.

- Fouled Tubes: In water-cooled chillers, the condenser and evaporator tubes play a critical role in transferring heat. Over time, these tubes can become fouled with dirt, scale, algae, or other deposits, especially when the water quality is poor or untreated. Fouled tubes restrict the flow of water and reduce the efficiency of heat transfer, which forces the chiller to consume more energy. Regular cleaning and tube brushing are necessary to prevent this issue and keep the system operating at peak performance.

- Electrical Faults: Chillers rely on a network of electrical components, including motors, contactors, sensors, and control systems. Issues such as voltage fluctuations, loose connections, short circuits, or faulty control boards can lead to unexpected shutdowns or erratic operation. In severe cases, these faults can damage critical parts like the compressor. Routine electrical inspections and timely replacement of worn-out components are essential to minimize downtime and ensure safe operation.

Chiller Maintenance Tips:

- Schedule Annual Inspections: Preventive maintenance begins with thorough and timely inspections. Having your chiller professionally inspected at least once a year helps detect small issues before they escalate into major problems. Technicians typically check refrigerant levels, electrical systems, control settings, water quality, and mechanical components during these inspections. Regular evaluations ensure that the chiller operates efficiently, extends equipment life, and complies with manufacturer warranty requirements.

- Use proper water treatment to prevent scaling in water-cooled systems: Scaling is one of the most common problems in water-cooled chillers and is caused by minerals like calcium and magnesium accumulating on heat exchange surfaces. This buildup acts as an insulating layer, significantly reducing the efficiency of heat transfer. A proper water treatment program—often involving filtration, chemical dosing, and softening—prevents scale formation, mitigates corrosion, and enhances the reliability of the entire chiller system.

- Regular lubrication for compressors and motors: Compressors and motors contain moving parts that generate friction during operation. Without adequate lubrication, these components can overheat, wear out faster, and eventually fail. Regularly lubricating bearings, motor shafts, and other mechanical parts reduces wear and tear, improves energy efficiency, and ensures smoother operation. Always follow the manufacturer’s guidelines regarding the type and frequency of lubrication.

- Clean condenser coils and tubes to maintain heat exchange efficiency: The condenser is responsible for rejecting heat absorbed by the refrigerant, and its efficiency depends heavily on clean, unobstructed coils and tubes. Dirt, dust, and biological growth can clog these components, forcing the chiller to work harder to dissipate heat. Regular cleaning of air-cooled condenser coils and brushing of water-side tubes keeps the heat exchange process efficient, lowers energy consumption, and helps maintain optimal cooling capacity.

How to Choose the Right Chiller

When selecting a chiller for your building or industrial need:

1. Capacity Requirements: Match Cooling Tonnage to Load

Choosing a chiller begins with accurately determining your building or process cooling load. Undersized chillers will struggle to maintain the desired temperature, resulting in inefficiency, poor performance, and equipment stress. Conversely, oversized chillers may cycle on and off too frequently, causing unnecessary wear and energy waste. Load calculations should factor in peak usage, ambient temperatures, internal heat gain, and any future expansion plans. An HVAC consultant or engineer can help assess the proper tonnage to ensure your chiller delivers consistent, efficient cooling.

2. Efficiency Ratings: Look for COP and IPLV

Energy efficiency is a crucial consideration, especially for large-scale or continuous operations. Two key performance metrics to evaluate are the COP (Coefficient of Performance) and IPLV (Integrated Part Load Value). COP measures a chiller’s efficiency at full load, while IPLV reflects performance during varying load conditions, which is more representative of real-world usage. Higher ratings mean the system uses less energy to produce the same cooling effect, translating to lower utility bills and reduced environmental impact. For long-term savings, always prioritize high-efficiency models—even if they cost more upfront.

3. Budget Considerations: Capital vs. Operational Costs

While upfront budget constraints are important, a true cost analysis should include both initial capital and ongoing operational expenses. Air-cooled chillers are generally less expensive to purchase and install, as they don’t require cooling towers or water treatment systems. However, they tend to consume more electricity over time. Water-cooled chillers, while more expensive initially, offer superior efficiency and lower energy costs—especially for large or continuously operating systems. Balancing both immediate affordability and lifecycle cost will help you make a financially sound decision.

4. Installation Constraints: Space, Noise, and Environmental Factors

Physical and environmental constraints often influence which type of chiller is most suitable. Air-cooled chillers are ideal for buildings with limited mechanical room space or where water availability is a concern, as they can be installed outdoors. However, they may generate more noise and be less efficient in hot climates. Water-cooled chillers, while quieter and more efficient, require ample space for cooling towers, pumps, and piping, and are better suited for larger facilities. Environmental factors such as local regulations, ambient temperatures, and water quality should also be taken into account during the selection process.

Future Trends in Chiller Technology

The chiller industry is evolving rapidly with innovations that prioritize efficiency and sustainability:

- Magnetic Bearing Chillers: Ultra-low maintenance, frictionless performance.

- AI Optimization: Predictive control and energy savings through machine learning.

- Eco-Friendly Refrigerants: Transitioning from R-22 to lower-GWP options like R-32, R-1234ze.

These technologies not only reduce carbon footprints but also align with green building certifications like LEED.

Conclusion: The Backbone of Modern Cooling

Chillers may be hidden away in mechanical rooms, but their role is front and center in maintaining indoor comfort and operational efficiency in modern infrastructure. Whether you’re designing a skyscraper or managing a manufacturing plant, the right chiller is essential for reliable, efficient cooling.

Explore more about HVAC technologies, trends, and maintenance guides on SmartHVACGuide.com.