Introduction to Vapour Compression Refrigeration Cycle (VCRC)

Refrigeration is an essential part of modern life, from preserving food in our homes to maintaining optimal temperatures in industrial processes. Among various refrigeration techniques, the Vapour Compression Refrigeration Cycle (VCRC) is the most widely used and efficient method for cooling. It powers everything from household refrigerators and air conditioners to large-scale industrial chillers.

In this in-depth guide, we will explore the working principles, key components, thermodynamic processes, performance metrics, and real-world applications of the Vapour Compression Refrigeration Cycle. Whether you’re an HVAC professional, mechanical engineering student, or a curious learner, this guide will help you understand why VCRC is the backbone of modern cooling systems.

What is the Vapour Compression Refrigeration Cycle?

The Vapour Compression Refrigeration Cycle (VCRC) is a thermodynamic process that transfers heat from a low-temperature region to a high-temperature region using mechanical energy. It operates in a closed loop, where a refrigerant absorbs heat in the evaporator and releases it in the condenser, enabling continuous cooling.

Why is VCRC the Most Popular Refrigeration Method?

High Efficiency – Provides better Coefficient of Performance (COP) compared to absorption or thermoelectric cooling.

Compact & Scalable – Suitable for small refrigerators to large industrial chillers.

Precise Temperature Control – Maintains consistent cooling performance.

Wide Range of Applications – Used in air conditioners, refrigerators, heat pumps, and cold storage plants.

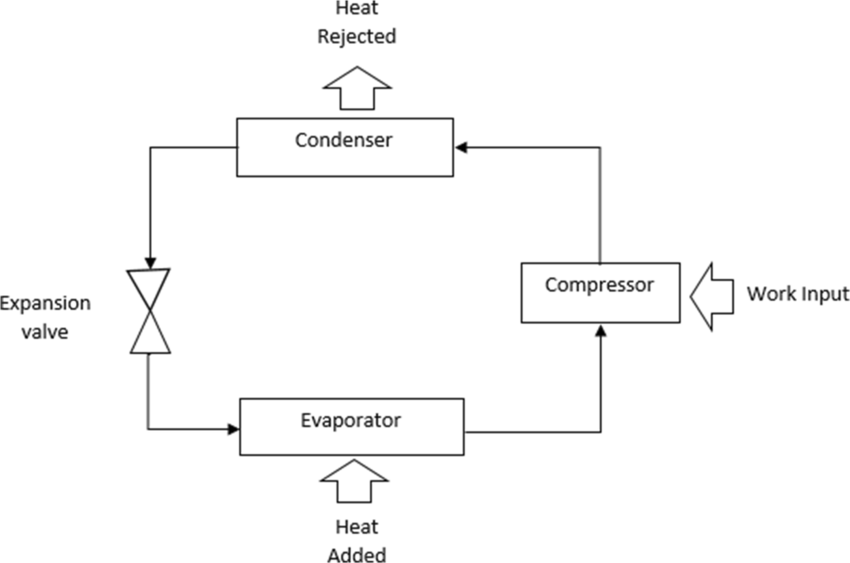

Key Components of the Vapour Compression Refrigeration Cycle

A VCRC system consists of four essential components, each playing a critical role in the refrigeration process:

1. Compressor – The Heart of the System

The compressor is responsible for increasing the pressure and temperature of the refrigerant vapor. It converts low-pressure gas (from the evaporator) into high-pressure, high-temperature vapor before sending it to the condenser.

Types of Compressors Used in VCRC:

- Reciprocating Compressors – Common in domestic refrigerators.

- Scroll Compressors – Used in split ACs (quiet & efficient).

- Screw Compressors – Ideal for large commercial & industrial systems.

- Centrifugal Compressors – Used in massive chillers (high capacity cooling).

2. Condenser – Heat Rejection Unit

The condenser removes heat from the high-pressure refrigerant vapor, converting it into a high-pressure liquid.

Types of Condensers:

- Air-Cooled Condensers – Used in small to medium HVAC systems.

- Water-Cooled Condensers – More efficient, used in central cooling plants.

- Evaporative Condensers – Best for dry climates (hybrid cooling).

3. Expansion Valve (Throttling Device) – Pressure & Temperature Regulator

The expansion valve reduces the refrigerant’s pressure and temperature, preparing it for the evaporator.

Common Types of Expansion Devices:

- Capillary Tube – Simple, fixed orifice (used in small refrigerators).

- Thermostatic Expansion Valve (TXV) – Adjusts flow based on evaporator temperature.

- Electronic Expansion Valve (EEV) – Smart, precise control in modern systems.

4. Evaporator – Where Cooling Happens

The evaporator absorbs heat from the surrounding air/fluid, turning the low-pressure liquid refrigerant into vapor, which then returns to the compressor to restart the cycle.

How Does the Vapour Compression Refrigeration Cycle Work? (Step-by-Step)

- Compression (Step 1-2)

- The compressor increases the refrigerant’s pressure & temperature.

- Low-pressure vapor → High-pressure superheated vapor.

- Condensation (Step 2-3)

- The hot refrigerant vapor flows into the condenser, releasing heat to the surroundings.

- Vapor → High-pressure liquid.

- Expansion (Step 3-4)

- The expansion valve reduces pressure, causing a temperature drop.

- High-pressure liquid → Low-pressure liquid-vapor mixture.

- Evaporation (Step 4-1)

- The cold refrigerant absorbs heat from the space being cooled, turning into low-pressure vapor.

- The cycle repeats continuously for sustained cooling.

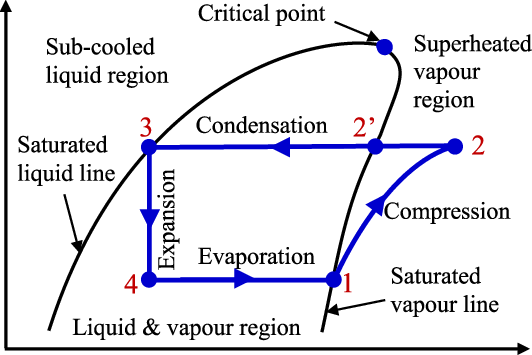

Thermodynamics of VCRC (P-h Diagram Analysis)

A Pressure-Enthalpy (P-h) Diagram helps visualize the four key thermodynamic processes in VCRC:

- Isentropic Compression (1-2) – No entropy change, but enthalpy increases.

- Isobaric Heat Rejection (2-3) – Constant pressure, refrigerant condenses.

- Isenthalpic Expansion (3-4) – No enthalpy change, but pressure drops sharply.

- Isobaric Heat Absorption (4-1) – Refrigerant evaporates, absorbing heat.

Understanding the P-h diagram helps engineers optimize system performance and diagnose inefficiencies.

Types of Vapour Compression Refrigeration Systems

1. Based on Configuration

- Single-Stage System – Used in homes, offices, and small commercial units.

- Cascade/Multi-Stage System – For ultra-low temperatures (medical freezers, industrial cooling).

2. Based on Heat Exchange Method

- Direct Expansion (DX) System – Refrigerant flows directly to the evaporator (common in ACs).

- Indirect Cooling System – Uses secondary coolant (glycol/brine) for large plants.

3. Based on Compressor Design

- Hermetic Compressors – Sealed units (low maintenance, used in fridges).

- Semi-Hermetic Compressors – Serviceable (commercial HVAC systems).

- Open Compressors – Industrial use (motor is external).

Refrigerants in VCRC: Environmental Impact & Selection

The choice of refrigerant affects efficiency, safety, and environmental sustainability.

Common Refrigerants & Their Properties

| Refrigerant | Application | ODP | GWP |

|---|---|---|---|

| R-134a | Domestic refrigerators | 0 | 1430 |

| R-410A (Phasing Out) | Modern ACs | 0 | 2088 |

| R-22 (Phased Out) | Old ACs | 0.05 | 1810 |

| R-600a (Isobutane) | Eco-friendly fridges | 0 | ~3 |

| R-290 (Propane) | Green refrigerant | 0 | ~3 |

Environmental Metrics

- Ozone Depletion Potential (ODP) – Should be 0 (non-ozone-depleting).

- Global Warming Potential (GWP) – Lower GWP = Better for climate (e.g., R-600a, R-290).

Applications of Vapour Compression Refrigeration Cycle

✔ Domestic Refrigeration (Refrigerators, Freezers)

✔ Air Conditioning (Split ACs, Central HVAC)

✔ Commercial Cooling (Supermarkets, Cold Storage)

✔ Industrial Processes (Pharmaceuticals, Food Processing)

✔ Transport Refrigeration (Reefer Trucks, Shipping Containers)

Conclusion: Why VCRC Dominates Modern Cooling?

The Vapour Compression Refrigeration Cycle remains the most efficient and widely adopted cooling technology due to its reliability, scalability, and energy efficiency. With advancements in compressor technology, eco-friendly refrigerants, and smart controls, VCRC continues to evolve, meeting the demands of sustainable cooling solutions.

If you’re looking for HVAC system optimization or refrigerant selection, understanding VCRC principles is essential for energy savings and environmental compliance.

🔹 Want to learn more about HVAC systems? Check out our other guides on Smart HVAC Guide!