Introduction

If you’ve ever passed by a large building or industrial plant and noticed steam billowing from tall structures, chances are you were looking at a cooling tower. These towers play a critical role in maintaining comfortable indoor environments and keeping industrial processes running efficiently. In this article, we’ll break down exactly what a cooling tower is, how it works, its different types, and where it’s commonly used. Whether you’re an HVAC professional, a facility manager, or just curious, this guide will help you understand cooling towers from the ground up.

What is a Cooling Tower?

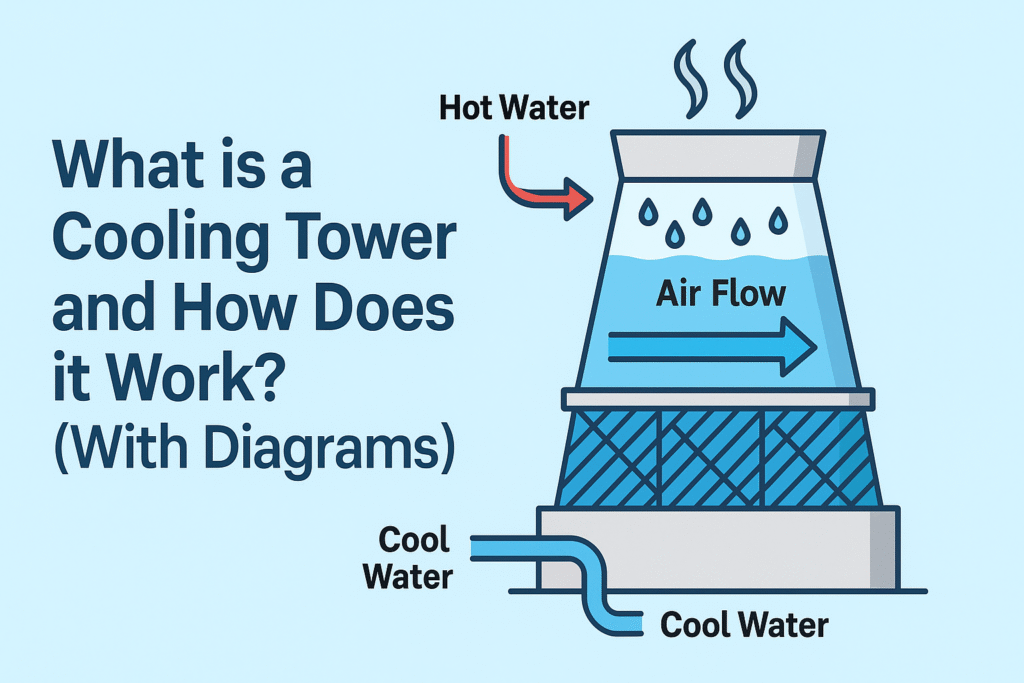

A cooling tower is a heat rejection device that removes unwanted heat from a building or industrial process by cooling down a stream of hot water. The cooled water is then recirculated back into the system. Cooling towers are most commonly used in HVAC systems and power plants where massive amounts of heat are generated and need to be efficiently dissipated.

The basic idea is simple: hot water enters the tower, gets cooled by air (either by direct contact or through a closed loop), and exits the tower at a much lower temperature. This process helps keep large systems from overheating and ensures they operate smoothly.

Cooling Tower Working Principle (Explained Simply)

The cooling tower works on a basic natural process: evaporation. It removes heat from water by letting a small portion of that water evaporate into the air. This evaporation carries away heat, which cools the remaining water. Here’s how the full process works:

1. Hot Water Enters the Cooling Tower

This process of heat transfer by evaporation is highly efficient and allows cooling towers to handle large volumes of water.

- The process begins when hot water comes from the HVAC system or industrial machinery that needs cooling.

- This water is pumped into the top of the cooling tower through a series of pipes.

2. Water is Sprayed Over Fill Media

- At the top, the hot water is distributed evenly over a material called the fill media (also known as “packing”).

- Fill media is designed with a large surface area, often in the form of thin plastic sheets or wooden slats with ridges.

- This material slows down the water flow and spreads it out, increasing the contact time between air and water.

3. Air is Drawn into the Tower

- At the same time, air is pulled into the tower—either:

- Naturally, using the draft created by the height of the tower (Natural Draft), or

- Mechanically, using large fans (Mechanical Draft).

- This air moves upward through the fill media as the water flows downward.

4. Evaporation Happens

- As the air and water come in contact, a small portion of the water (about 1–2%) evaporates.

- Evaporation removes heat from the water because it takes energy (in the form of heat) to convert water from liquid to vapor.

- This means the remaining water cools down significantly.

5. Cooled Water Collects in the Basin

- After passing through the fill media and losing some heat through evaporation, the now-cooled water drips down and collects in the cold water basin at the bottom of the tower.

- From there, this cooled water is pumped back into the building or industrial process to absorb more heat—starting the cycle again.

This process of heat transfer by evaporation is highly efficient and allows cooling towers to handle large volumes of water.

Main Components of a Cooling Tower

A cooling tower is a complex yet well-coordinated system designed to reject heat from water through the process of evaporation. Each component plays a critical role in making the system efficient and reliable.

1. Fill Media

Function: Increases surface area for water-air interaction.

- Fill media is a network of thin surfaces or sheets made of plastic or wood arranged in a crisscross or honeycomb structure.

- As hot water flows over this media, it spreads into a thin film or breaks into droplets.

- This increases the contact area and contact time between water and air, improving evaporative cooling efficiency.

- There are two main types: film fill and splash fill.

2. Drift Eliminators

Function: Prevent water droplets from escaping the tower with exhaust air.

- As air flows out of the tower, small water droplets (called drift) may escape with it.

- Drift eliminators are placed near the air outlet and are designed with zig-zag channels or baffles.

- They capture and redirect these droplets back into the system, reducing water loss and preventing environmental issues (like wetting nearby structures).

3. Nozzles

Function: Spray hot water evenly over the fill media.

- Nozzles are part of the water distribution system.

- Their job is to break up the incoming hot water into fine droplets and spray it evenly over the fill.

- This ensures maximum coverage and efficient heat transfer.

- They can be fixed, rotating, or pressurized, depending on the tower design.

4. Water Distribution System

Function: Delivers hot water to the top of the tower and distributes it uniformly.

- This system consists of pipes, valves, and headers that bring hot water from the chiller or process.

- It ensures the water is evenly distributed to all nozzles for consistent cooling performance.

- An uneven water spread can reduce efficiency and cause dry spots in the fill.

5. Fan (in Mechanical Draft Towers)

Function: Draws or pushes air through the tower.

- In mechanical draft cooling towers, fans are used to force or draw air through the system.

- There are two main types:

- Induced draft: Fan is at the top and pulls air upward.

- Forced draft: Fan is at the side and pushes air inward.

- Fans are essential for controlling airflow, which is key to the evaporative cooling process.

6. Air Inlet Louvers

Function: Allow air in while keeping out debris and sunlight.

- Louvers are slatted openings on the side of the cooling tower.

- They guide air into the fill section while preventing large particles, birds, insects, and sunlight (which can cause algae growth) from entering.

- They also help reduce splash-out and improve tower appearance.

7. Cold Water Basin

Function: Collects and stores cooled water before it is recirculated.

- Located at the bottom of the cooling tower, the cold water basin collects the cooled water after it has passed through the fill media.

- From here, the water is pumped back to the HVAC system, chiller, or process equipment.

- The basin may have filters, sumps, or strainers to remove any debris before recirculation.

8. Casing (Tower Body or Enclosure)

Function: Protects internal components and supports the structure.

- The casing is the outer shell of the cooling tower.

- It contains and supports all the internal parts—fill, fan, nozzles, drift eliminators, and water distribution system.

- It is made from materials like fiberglass, galvanized steel, concrete, or PVC, depending on the application.

- It also helps direct airflow and prevents leakage.

These components work together to ensure efficient cooling performance.

Types of Cooling Towers

Cooling towers come in different designs, each suited for specific applications. Here are the main types:

1. Based on Air Flow:

Natural Draft Cooling Towers

Natural draft cooling towers use the natural buoyancy of warm air to create airflow, rather than relying on mechanical fans. These towers are typically tall, hyperbolic structures that take advantage of the temperature difference between the warm, moist air inside the tower and the cooler, drier outside air. As hot water enters and flows over the fill media, it transfers heat to the air. The heated air becomes lighter and rises naturally through the chimney-like structure, drawing in cooler air from the bottom. This continuous upward flow enables the evaporation process without any moving parts. Natural draft towers are highly energy-efficient and are commonly used in large-scale applications such as power plants and heavy industrial facilities where large volumes of heat must be rejected.

Mechanical Draft Cooling Towers

Mechanical draft cooling towers use one or more powered fans to force or draw air through the tower, making them more compact and flexible than natural draft towers. These towers are commonly used in commercial buildings, HVAC systems, and industrial processes where precise and controlled cooling is required. There are two main types: induced draft (where fans are placed at the top to pull air upward) and forced draft (where fans are placed at the base to push air through the tower). By actively controlling airflow, mechanical draft towers can operate efficiently in a wide range of weather conditions and offer better performance in limited space. However, they do consume more energy due to the use of fans.

2. Based on Circuit:

Open-Circuit Cooling Tower

An open-circuit cooling tower, also known as a wet cooling tower, is the most common type used in HVAC and industrial applications. In this system, hot water from the process or chiller is directly exposed to the air inside the tower. The water is sprayed over the fill media, increasing the surface area for evaporation. As air flows through the tower—either naturally or mechanically—a small portion of the water evaporates, carrying away heat and cooling the remaining water. The cooled water then collects in a basin and is pumped back into the system. Since the water comes into direct contact with air, open-circuit towers are highly efficient in removing heat, but they do require water treatment to manage issues like scaling, algae growth, and contamination.

Closed-Circuit Cooling Tower

A closed-circuit cooling tower, also known as a dry-wet cooling tower or fluid cooler, cools process fluids without exposing them directly to the outside air. In this system, the process fluid (such as water or a glycol mixture) circulates through a closed-loop coil. Air flows over this coil, and water is sprayed over the outside of the coil to enhance heat transfer. As the spray water evaporates, it removes heat from the fluid inside the coil. Since the process fluid stays enclosed and doesn’t come in direct contact with air, it remains clean and free from contamination. Closed-circuit towers are ideal for applications where fluid purity is critical or where water loss must be minimized. They also reduce the need for extensive water treatment compared to open-circuit systems.

3. Based on Build Type:

Package (Modular) Cooling Towers

Package cooling towers, also known as modular cooling towers, are pre-engineered, factory-assembled units designed for quick installation and compact spaces. These towers come as complete systems with all essential components—such as fill media, fans, nozzles, and water basins—integrated into a single, self-contained unit. Because of their modular design, multiple units can be connected to handle larger loads, making them highly scalable. Package cooling towers are ideal for commercial buildings, data centers, and small to mid-sized industrial applications. They offer easy transportation, faster setup, and reduced on-site construction costs, while still providing efficient heat rejection. Maintenance is also simplified due to standardized components and accessible layouts.

Field-Erected Cooling Towers

Field-erected cooling towers are large, custom-built structures assembled on-site to meet the specific cooling needs of industrial plants, power stations, refineries, and other high-capacity applications. Unlike factory-assembled package towers, these systems are constructed piece by piece using materials such as concrete, fiberglass, or steel. They are highly customizable in terms of size, airflow design (natural or mechanical draft), and performance specifications. Field-erected towers are ideal for handling very large water volumes and continuous heavy-duty operation. While they require longer installation times and higher initial costs, their durability, scalability, and long-term efficiency make them the preferred choice for mission-critical cooling in large-scale industries.

Each type has its pros and cons depending on the cooling load, water quality, and maintenance requirements.

Cooling Tower Applications

Cooling towers are used in a wide range of environments where heat removal is essential. Some common applications include:

- Commercial Buildings: Office complexes, malls, and hospitals use cooling towers as part of their HVAC systems.

- Industrial Plants: Manufacturing units, chemical factories, and oil refineries rely on cooling towers to regulate process temperatures.

- Power Plants: Cooling towers are vital for dissipating heat generated during electricity production.

- Data Centers: To maintain optimal operating temperatures for servers and IT infrastructure.

- Cold Storage Facilities: Used to manage refrigeration system heat loads.

Cooling Tower vs. Chiller: What’s the Difference?

People often confuse cooling towers and chillers, but they serve different purposes and often work together.

- Cooling Tower: Removes heat from water via evaporation or air exchange.

- Chiller: Uses a refrigeration cycle to remove heat from water or air.

While a chiller actively cools the water using compressors and refrigerants, a cooling tower passively removes heat from the condenser water loop. In most large HVAC systems, chillers and cooling towers operate in tandem for maximum efficiency.

| Feature | Cooling Tower | Chiller |

| Cooling Method | Evaporative/Air-based | Refrigerant-based |

| Energy Efficiency | Very High (passive) | Moderate to High |

| Common Use | HVAC & Industrial Systems | HVAC & Process Cooling |

| Initial Cost | Lower | Higher |

Advantages of Cooling Towers

Cooling towers offer several benefits, especially in large-scale operations:

Energy Efficiency

Cooling towers are highly energy-efficient because they rely on the natural process of evaporation to remove heat from water. This significantly reduces the need for energy-intensive mechanical refrigeration, leading to lower electricity bills and operational costs—especially in large-scale facilities.

Environmentally Friendly

Since cooling towers use air and water to transfer heat, they minimize the need for synthetic refrigerants, which are often harmful to the environment. This makes them a greener alternative in HVAC and industrial applications, supporting sustainable and eco-friendly operations.

Scalable Design

Cooling towers are available in various sizes and configurations, making them ideal for both small commercial buildings and large industrial plants. Their modular or customizable designs allow them to scale up or down based on specific cooling requirements.

Cost-Effective

Compared to systems like mechanical chillers, cooling towers are generally more cost-effective to install and operate. They offer excellent long-term value by reducing energy consumption, requiring less maintenance, and using simple technologies that are easy to manage.

Water Reuse

Cooling towers are designed to recirculate water, meaning the same water is used repeatedly within the system. This greatly reduces water waste and lowers the need for continuous water supply, making them efficient in regions where water conservation is a priority.

Common Cooling Tower Problems & Maintenance Tips

To keep your cooling tower performing at its best, regular maintenance is essential. Common issues include:

- Scaling occurs when minerals—especially calcium and magnesium—present in hard water start to deposit on internal surfaces like the fill, pipes, and heat exchange surfaces. Over time, this buildup reduces heat transfer efficiency, restricts water flow, and can lead to equipment damage if not properly treated.

- Fouling is the accumulation of biological matter, dirt, algae, or other particulates within the cooling tower system. These deposits can clog the fill media and piping, lower system efficiency, and create breeding grounds for bacteria. Regular cleaning and filtration are essential to prevent fouling.

- Corrosion is the gradual deterioration of metal components caused by chemical reactions with water, air, or contaminants. It can weaken structural elements and cause leaks, leading to safety concerns and expensive repairs. Using corrosion-resistant materials and chemical treatment helps control this issue.

- Drift refers to tiny water droplets that escape the tower along with exhaust air. While drift is expected in small amounts, excessive drift leads to water loss and can cause moisture damage to nearby structures. Drift eliminators are used to reduce this problem.

- Legionella bacteria can grow in warm, stagnant water often found in poorly maintained cooling towers. If aerosolized and inhaled, it can cause Legionnaires’ disease, a severe type of pneumonia. Preventing this risk requires regular water treatment, monitoring, and system disinfection.

Maintenance Tips:

- Schedule regular cleaning

- Treat the water to prevent scaling and bacteria

- Inspect fans, motors, and fill media periodically

- Monitor system pressure and temperature

FAQs

Q: What is the function of a cooling tower in HVAC?

A cooling tower removes heat from the HVAC system by cooling hot water and returning it to the chiller or condenser.

Q: What are the different types of cooling towers?

Types include open-circuit, closed-circuit, natural draft, and mechanical draft cooling towers.

Q: How does a cooling tower reduce temperature?

It reduces water temperature through evaporation and heat exchange with air.

Q: Can cooling towers be used in residential buildings?

Generally, no, cooling towers are more suited for large commercial and industrial systems.

Conclusion

Understanding how a cooling tower works and where it’s used can help facility managers, engineers, and even building owners make informed decisions about their HVAC and process cooling needs. These systems are essential for efficient temperature control in large-scale operations and offer numerous benefits in terms of energy savings and sustainability. Whether you’re looking to upgrade your cooling system or just want to learn more, knowing the basics of cooling towers is a great place to start.