Introduction

In the world of heating, ventilation, and air conditioning (HVAC), airflow is not just important — it’s essential. Every HVAC system, from a small residential air conditioner to a large-scale industrial air handling unit, depends on controlled air movement to function properly. That movement is achieved by two critical components: fans and blowers. These mechanical devices might seem simple, but they are at the core of indoor climate control, air distribution, and air quality management.

Without fans and blowers, air wouldn’t circulate, and HVAC systems wouldn’t be able to deliver conditioned air to different parts of a building. They are the workhorses behind ventilation, cooling, and heating functions. In this comprehensive guide, we’ll explore the different types of fans and blowers used in HVAC systems, understand their individual characteristics, and compare their advantages and disadvantages. Whether you’re an HVAC professional or a curious homeowner, this article will help you choose the right device for your system and ensure maximum efficiency and performance.

What Are HVAC Fans and Blowers?

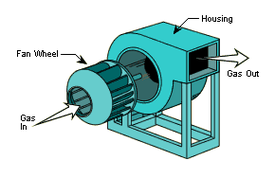

Fans and blowers are both used to move air, but they do so in different ways and are designed for different applications within HVAC systems. A fan is typically used to circulate air at low pressure over a large area. It moves a high volume of air at low speed and pressure, making it ideal for general ventilation. A blower, on the other hand, is designed to push air at a higher pressure through a more confined space like ducts or filters. It delivers a focused stream of air and is used when resistance in the airflow path is high.

How They Work

- Fans: Use rotating blades to draw air in and discharge it along the axis or at a slight angle. Air movement is more diffused and typically less forceful.

- Blowers: Use centrifugal force or positive displacement to move air more aggressively. The air is usually forced through a confined space, making blowers effective in high-resistance systems.

In HVAC systems, both components are indispensable. Fans are often found in cooling towers, exhaust systems, and return air systems, while blowers are used in air handlers, furnaces, and ducted heating/cooling setups.

Key Differences Between Fans and Blowers

Although both devices move air, understanding the differences between fans and blowers is important for choosing the right component for your system. Let’s break it down:

| Feature | Fans | Blowers |

| Air Pressure | Low (below 1.2 psi) | Medium to High (1.2 psi to 15 psi) |

| Airflow Direction | Dispersed or axial | Focused and directed |

| Speed | High RPM, low torque | Lower RPM, higher torque |

| Volume | High volume, low pressure | Moderate volume, high pressure |

| Application | Ventilation, cooling towers, AHUs | Duct systems, industrial exhausts |

| Noise | Usually quieter | Louder due to high-speed compression |

| Maintenance | Typically less | More frequent due to moving components |

Use fans for open space ventilation and light-duty applications. Use blowers when airflow needs to overcome resistance from filters, duct bends, or when pressurized air delivery is required.

Types of HVAC Fans

Fans in HVAC systems are selected based on their airflow needs, pressure requirements, noise constraints, and energy efficiency. Here’s a deeper look at each type:

Axial Fans

Axial fans move air parallel to the fan’s axis, just like a household ceiling fan or propeller. They are designed to handle large volumes of air with minimal resistance.

- Used in: Industrial ventilation, cooling towers, bathroom exhausts, condenser units

- Pros: Simple design, high airflow rate, energy-efficient at low pressure

- Cons: Poor performance in high-resistance systems (e.g., long ducts or filters)

- Best For: Open spaces or applications with minimal static pressure

Centrifugal Fans

Also called radial fans, centrifugal fans draw air into the center of the fan and then blow it out at a 90-degree angle. The design allows them to generate higher static pressure.

- Used in: AHUs, HVAC duct systems, commercial HVAC units

- Pros: Great for medium-to-high static pressure systems, highly durable

- Cons: Bulkier, typically louder than axial fans

- Best For: HVAC applications involving ductwork, filtration, and multiple bends

Inline Fans

Inline fans are cylindrical fans designed to be mounted within the duct itself, often used to assist air movement over long duct runs.

- Used in: Kitchen exhausts, bathroom ventilation, grow rooms

- Pros: Space-saving, quiet, easy to install

- Cons: May lack the force required for high-resistance systems

- Best For: Supplemental ventilation in residential or light commercial setups

Plenum Fans

Plenum fans are beltless, direct-drive fans placed directly inside the AHU or air distribution box (plenum). They eliminate the need for fan housing.

- Used in: Modern air handling units, commercial HVAC systems

- Pros: Low noise, high efficiency, compact footprint

- Cons: Higher initial cost and installation complexity

- Best For: Applications requiring quiet operation and high system flexibility

Crossflow Fans

Crossflow (or tangential) fans have a cylindrical shape and provide a wide sheet of airflow across the entire length of the fan.

- Used in: Window AC units, ductless split systems

- Pros: Provides uniform airflow, compact

- Cons: Limited static pressure, not suitable for large systems

- Best For: Small appliances and local air distribution

Types of HVAC Blowers

Blowers are typically selected for their pressure-handling capability, air volume, and noise tolerance. Let’s explore the main types:

Forward-Curved Blowers

These blowers feature blades curved in the direction of rotation. They are usually compact and quiet, but they are best suited for low-pressure applications.

- Used in: Residential air handlers, HVAC furnaces, small ventilation units

- Pros: Quiet, compact, simple design

- Cons: Less efficient at high pressure, prone to overloading

- Best For: Residential or small commercial HVAC units with limited resistance

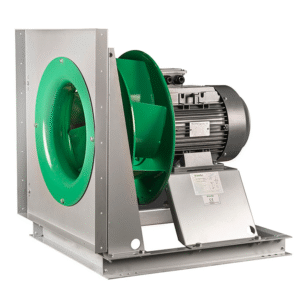

Backward-Curved Blowers

With blades curved away from the rotation direction, these blowers handle higher pressures and are more energy-efficient.

- Used in: Commercial air handlers, rooftop units

- Pros: Energy efficient, handles high resistance without overloading

- Cons: Louder and more expensive than forward-curved models

- Best For: Medium to large commercial HVAC systems

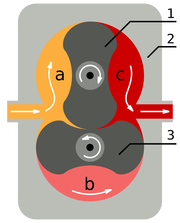

Positive Displacement Blowers

Unlike centrifugal models, positive displacement blowers trap a fixed volume of air and push it through the outlet.

- Used in: Cleanrooms, chemical labs, and specialized industrial applications

- Pros: Consistent airflow under varying conditions

- Cons: Higher cost, requires regular maintenance

- Best For: Precision airflow control and high-resistance environments

Plug Fans

A type of backward-inclined blower mounted inside an enclosure, plug fans are used in systems requiring modularity and direct drive.

- Used in: Hospitals, data centers, cleanrooms

- Pros: High efficiency, compact design, low maintenance

- Cons: Higher upfront cost

- Best For: Modern AHU designs with minimal energy loss

Applications of Fans and Blowers in HVAC Systems

HVAC fans and blowers are used in nearly every building type, from homes and apartments to hospitals and data centers. Each setting has unique airflow needs, and different types of fans and blowers are deployed accordingly.

Residential Applications

- Circulating air in central HVAC systems to maintain even temperature

- Exhausting air from bathrooms, kitchens, and laundry rooms

- Providing fresh air intake in newer homes with airtight construction

- Assisting heat exchangers and indoor coils in split air conditioners

Commercial Applications

- Ventilating large buildings like malls, airports, and office spaces

- Used in Air Handling Units (AHUs) for consistent air movement across zones

- Employed in rooftop units (RTUs) for space-saving HVAC solutions

- Maintaining air quality in commercial kitchens and restrooms

Industrial Applications

- Removing heat and airborne contaminants in factories or warehouses

- Regulating air changes per hour in cleanrooms and pharmaceutical facilities

- Providing cooling in data centers where equipment heat load is high

- Handling exhaust in chemical processing units or power plants

Correct fan and blower selection ensures energy-efficient operation and compliance with building ventilation codes and indoor air quality (IAQ) standards.

For detailed information on cleanroom HVAC systems, see our Guide to HVAC in Cleanrooms.

Factors to Consider When Selecting a Fan or Blower

Making the right choice between a fan and a blower involves evaluating multiple technical and site-specific factors:

- Air Volume (CFM): Determine the amount of air (in cubic feet per minute) that needs to be moved.

- Static Pressure (SP): Calculate the total resistance the air will encounter in the duct system.

- Duct Layout: Long ducts with many bends require blowers with higher pressure capacity.

- Installation Space: Some environments need compact units like inline or plenum fans.

- Energy Efficiency: Consider EC motors or VFDs to control motor speed and save energy.

- Noise Levels: In hospitals, schools, or residences, quiet fans are preferable.

- Maintenance Access: Belt-driven fans require more upkeep than direct-drive units.

- Environment: Ensure the fan or blower can handle the ambient temperature and humidity.

Working with HVAC consultants or using manufacturer selection tools can further ensure correct sizing and performance.

Advantages and Disadvantages Summary Table

| Type | Advantages | Disadvantages |

| Axial Fans | High airflow, cost-effective | Low pressure capability |

| Centrifugal Fans | High pressure, reliable | Noisier, larger size |

| Inline Fans | Compact, easy to install | Limited airflow capacity |

| Forward-Curved Blowers | Quiet, compact | Low efficiency at high pressure |

| Backward-Curved Blowers | Efficient, powerful | Higher initial cost |

| Plug Fans | Compact, energy-efficient | Expensive, advanced setup |

Maintenance Tips for HVAC Fans and Blowers

Proper maintenance of fans and blowers is crucial to ensure their longevity and optimal performance. Here’s how to keep them in top condition:

- Clean Blades and Housings: Dust and debris can accumulate and affect airflow and efficiency.

- Lubricate Bearings: Periodic lubrication reduces friction and prevents wear in motor components.

- Inspect Belts: Check for tension and wear in belt-driven units and replace when necessary.

- Monitor Noise and Vibration: Unusual sounds often indicate mechanical imbalance or loose components.

- Check Alignment: Misalignment can lead to excessive vibration and energy loss.

- Replace Filters: Dirty filters cause blowers to work harder, increasing energy use and wear.

- Verify Electrical Connections: Ensure wiring and terminals are tight and corrosion-free.

- Review Manufacturer Guidelines: Always follow the specific maintenance instructions provided by the equipment supplier.

Regular inspections — ideally scheduled quarterly — can significantly reduce the risk of failure and lower energy bills.

Conclusion

Fans and blowers are the lifeblood of any HVAC system. From simple axial fans to sophisticated backward-curved blowers, each type serves a unique purpose depending on the system’s design and requirements. By understanding the differences between fans and blowers, their types, and where they are best used, HVAC professionals and building owners can make informed decisions that improve comfort, efficiency, and air quality.

Whether you’re upgrading an old system, installing a new one, or just want to learn more, always consider airflow needs, pressure requirements, energy use, and ease of maintenance. Choosing the right fan or blower not only enhances HVAC performance but also contributes to sustainability and cost-effectiveness.

FAQs

What is the main difference between a fan and a blower?

Fans move large volumes of air at low pressure, while blowers push air at higher pressure through ducts or restricted pathways.

Can I replace a blower with a fan in my HVAC system?

Generally no. Blowers are designed for high-resistance applications, and replacing them with fans can reduce system efficiency.

Which type of fan is best for ducted systems?

Centrifugal or backward-curved fans are ideal for ducted HVAC systems due to their ability to handle static pressure.

Are plug fans more efficient than belt-driven models?

Yes. Plug fans are typically direct-drive and eliminate the energy losses associated with belts and pulleys.

How often should HVAC fans and blowers be serviced?

Ideally, inspect them every 3–6 months. Cleaning, lubrication, and belt inspection should be done based on usage and environment.